Everything about automatic watches and how they work

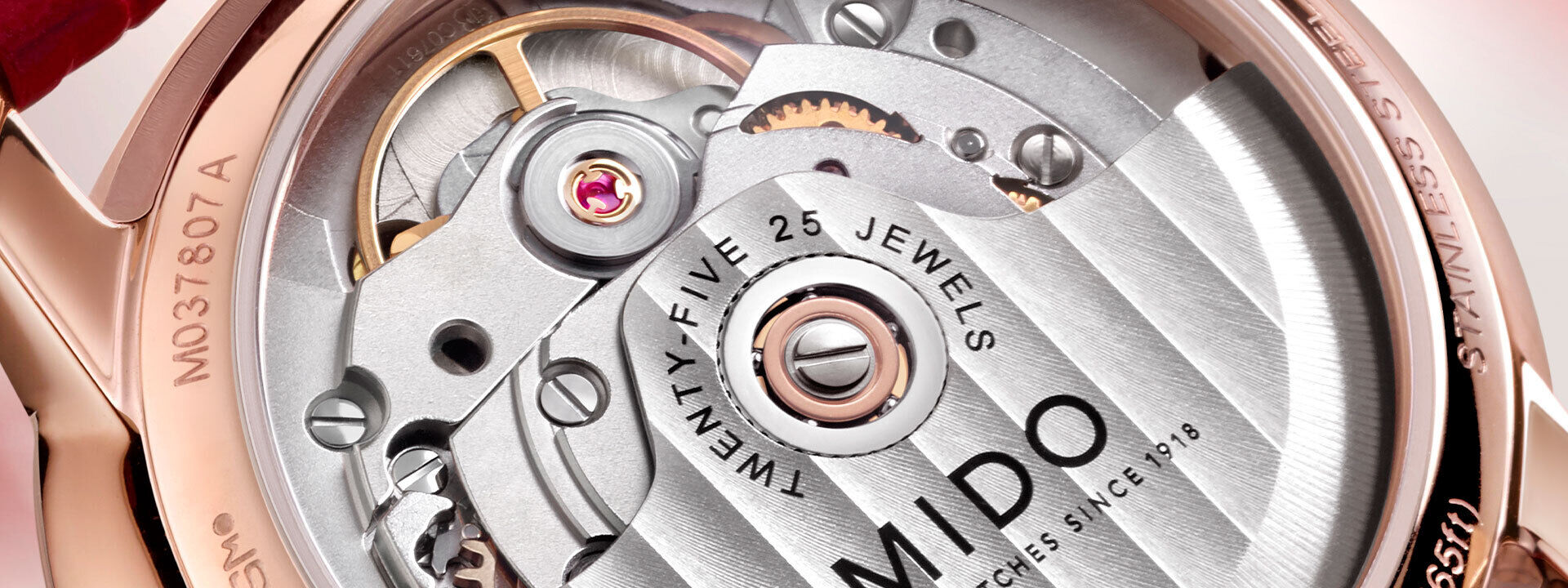

If your automatic watch has a visible caseback, like the Mido Commander, you can easily see the rotor. The semicircular and movable rotor is, seen from here, the uppermost part of the movement of an automatic watch and vibrates when you set your watch in motion. By the fact that the spring wants to get back to its original, unstressed form, the actual driving force is now generated. The spring, which is made of a fine wire and spirals, is located in the so-called "spring barrel" of the automatic watch. A slipping clutch (also called a "bridge") prevents the spring from overwinding. Thus, a watch cannot be moved too much.

The energy generated by the spring's desire to uncoil is transmitted to the gear train. The gear train consists of the minute wheel, the intermediate wheel and the fourth wheel, which can be visually imagined as small toothed wheels connected in sequence. The large minute wheel is directly connected to the mainspring barrel and is the first to absorb the driving force of the mainspring. The minute wheel of an automatic watch needs exactly 60 minutes for one complete revolution.

Through the "minute tube" of an automatic watch, the wheel is connected to the minute hand on the dial. Inside the watch, the minute wheel is followed by the intermediate wheel, which in turn is connected to the second wheel. Which - logically - usually takes 60 seconds for one revolution and is connected to the second hand. Since the wheels in the movement of an automatic watch run smoothly, the hands do not jump from one field to the next, as in a quartz watch, but glide continuously across the dial.

The fourth wheel now meshes with the escape wheel, the first part of the escapement. This consists of the escape wheel, escapement wheel, and the balance wheel attached to it. The escapement's task is to concentrate the driving force, i.e. to "inhibit" it. This prevents the energy of the barrel from being released too quickly.

In the history of watchmaking, over 250 different escapement systems have been developed, with the Swiss lever escapement being found in most modern wristwatches. The Swiss lever escapement is one of the "free" escapements. Free because the balance wheel rotates freely after the initial impulse from the pallet. The anchor acts like a pendulum swinging back and forth, hooking into the escape wheel (also a gear wheel, which is set in motion by the spring via the pre-staggered gears) and thus bringing it to a stop at regular intervals.

By the way, the famous "tick tock" sound of an automatic watch is caused by the escape wheel teeth hitting the plate jewels of the escape arms. Since these are of different lengths, it makes a "tick tock" sound rather than a steady "tick tock" sound. The actual clock generator in the background of the gears is the so-called balance wheel. The balance looks like a rotor blade that can swing back and forth in the middle of a round metal frame - that's why this part of the movement of automatic watches is also called the oscillating system. After the escape wheel and anchor are set in motion by the fourth wheel, the balance is also moved by the balance shaft, which is connected to the anchor, and starts its first semi-oscillation.

When the balance returns from the half oscillation, its lever engages the pallet again and moves it further. To ensure that an automatic watch runs accurately, the number of semi-oscillations of the balance is fixed (usually 21,600 or 28,800 oscillations per hour in modern watches). At first glance, the interaction between the pallet, escape wheel and balance looks more complicated than it is: ultimately, the escape wheel is set in motion by the gear train. This movement is passed on to the escapement wheel and thus to the balance. The interaction of these two elements now "inhibits" the movement of the escape wheel again and gives the automatic watch its beat.

The escapement with the balance is located at the end of the gear train and is, so to speak, the last link in the chain of the automatic movement. At the same time, however, it is also the clock generator for all the upstream elements and ensures that all the other wheels run in time, so that the hands also tell the time as precisely as possible. In a quartz movement, the component that determines the rate (the stepper motor) is located at the beginning of the chain, i.e. before the gears that are connected to the watch hands.

Summary: Kinetic energy expands the spring in the barrel of the automatic watch. This now pulls it back into its original form due to physical laws. This movement is now transmitted to the downstream gear train, which is connected to the hands on the dial. The escapement at the end of the gear train now gives the entire process the necessary beat.

The balance performs its semi-oscillations and thus ensures that the pallet lever engages the escape wheel and stops it at regular intervals. This also stops the upstream wheels and counteracts a too rapid "unloading" of the cocked spring. Through this regulation of the wheels, the hands on the dial ultimately run accurately in time.

Do not let yourself be confused by different formulations. The escape wheel is often referred to as the escapement wheel, but this does not mean that there are any differences in the way it works. Sometimes, the escapement wheel is simply called "escapement piece" and the balance wheel is called "rate regulator". The power reserve indicates how long the movement of the automatic watch is supplied with energy by the mainspring barrel without having to be moved. Depending on the manufacturer and model, this is usually between 24 and 60 hours.

By means of "watch winders", such as the Chronovision Ambiance III, an automatic watch can be set in motion even when it is not currently being worn on the wrist. This eliminates the need for manual winding after a long break. If you wind your automatic watch manually, you should make sure that you stop turning when you feel a noticeable resistance (the slipping clutch).

By the way, most automatic watches are wound clockwise. However, turning the crown in the wrong direction is not harmful on most models thanks to the sawtooth-shaped teeth of the winding mechanism. Before you start working on your automatic watches yourself, you should take a look at your watch's manual. For most models, these are available for free on the Internet.